IndyCar Technology

Anatomy of an IndyCar

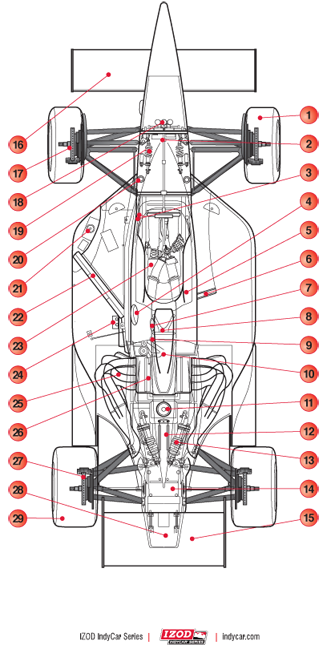

1. Front tire 2. Center spine 3. Anti-roll bar adjusters 4. Refueling adapter

5. Headrest structure 6. Oil cooler 7. Fuel vent 8. Roll hoop 9. Air jack fitting

10. Air inlet 11. Oil scanvenge tower 12. Rear anti-roll bar assembly 13. Rear damper/spring assembly

14. Transmission/Gearbox 15. Rear wing 16. Front wing 17. Front brake disc

18. Brake master cylinder 19. Front spring/damper unit 20. Front air jack 21. Engine Control Unit

22. Water radiator 23. Molded seat 24. Impact lights 25. Exhaust system

26. Air box 27. Rear brake disc 28. Rear attenuator 29. Rear tire

FRONT WING: The front wing (16) works in conjunction with the rear wing to create aerodynamic downforce and balance between the front and the rear of the car. There are two different front wing configurations: speedway and short oval/road course. The front wing can be adjusted during a race to improve handling.

REAR WING: The rear wing (15) works in conjunction with the front wing to create aerodynamic downforce and balance between the front and the rear of the car. There are three different rear wing configurations: superspeedway, intermediate tracks and short ovals/road courses.

CHASSIS: The central part of the car, including the driver’s compartment. The chassis is constructed of carbon fiber with an aluminum honeycomb core. As the frame of the car, the chassis houses the center spine (2), anti-roll bar adjusters (3), the refueling adaptor (4), headrest structure (5), fuel vent (7), roll hoop (8), air jack fitting (9), air inlet (10), brake master cylinder (18), front spring/damper unit (19), front air jack (20), molded seat (23) and impact lights (24).

SIDE POD: Also included in the chassis is the side pod, the bodywork on the side of the car covering the oil cooler (6), engine control unit (21) and water radiator (22). The side pod and its components aid in engine cooling, car aerodynamics and driver protection in case of a side impact.

FUEL CELL: The fuel cell is made of rubber and is covered with a Kevlar-fitted blanket for extra protection in side impacts. It holds 22 gallons of 100 percent fuel grade ethanol.

GEARBOX/BELLHOUSING: An IZOD IndyCar Series car features an assisted gear shift system utilizing paddle shifting. Paddles are located on the back of the steering wheel, with the right paddle moving up gears and the left paddle moving down gears. The bellhousing connects the gearbox to the engine. Key components of the gear box/bellhousing include the oil scavenger tower (11), rear anti-roll bar assembly (12), rear damper/spring assembly (13), transmission (14) and rear attenuator (28).

ENGINE: The IZOD IndyCar Series utilizes the normally-aspirated, 3.5-liter Honda Indy V-8 engine has 650 horsepower. It has four valves per cylinder. The 3.5 liter provides longer engine life between rebuilds and additional mid-range torque for the varied IZOD IndyCar Series schedule – from street/road courses to short ovals to superspeedways. The engine houses the exhaust system (25) and the air box (26).

TIRES: Firestone Firehawk racing radials are mounted on 15-inch rims with front tires (1) approximately 11 inches wide and rear tires (29) approximately15 inches wide. The weight of an IZOD IndyCar Series car at is speed is approximately four times the static weight, so the tire sidewalls have to strong enough to handle the stress, yet thin enough to dissipate heat.

FRONT/REAR SUSPENSION: The front and rear suspension attach the wheels to the chassis. It is designed to withstand all the braking and acceleration loads in addition to vertical loads. The suspension includes the front brake disc (17) and rear brake disc (27).

5. Headrest structure 6. Oil cooler 7. Fuel vent 8. Roll hoop 9. Air jack fitting

10. Air inlet 11. Oil scanvenge tower 12. Rear anti-roll bar assembly 13. Rear damper/spring assembly

14. Transmission/Gearbox 15. Rear wing 16. Front wing 17. Front brake disc

18. Brake master cylinder 19. Front spring/damper unit 20. Front air jack 21. Engine Control Unit

22. Water radiator 23. Molded seat 24. Impact lights 25. Exhaust system

26. Air box 27. Rear brake disc 28. Rear attenuator 29. Rear tire

FRONT WING: The front wing (16) works in conjunction with the rear wing to create aerodynamic downforce and balance between the front and the rear of the car. There are two different front wing configurations: speedway and short oval/road course. The front wing can be adjusted during a race to improve handling.

REAR WING: The rear wing (15) works in conjunction with the front wing to create aerodynamic downforce and balance between the front and the rear of the car. There are three different rear wing configurations: superspeedway, intermediate tracks and short ovals/road courses.

CHASSIS: The central part of the car, including the driver’s compartment. The chassis is constructed of carbon fiber with an aluminum honeycomb core. As the frame of the car, the chassis houses the center spine (2), anti-roll bar adjusters (3), the refueling adaptor (4), headrest structure (5), fuel vent (7), roll hoop (8), air jack fitting (9), air inlet (10), brake master cylinder (18), front spring/damper unit (19), front air jack (20), molded seat (23) and impact lights (24).

SIDE POD: Also included in the chassis is the side pod, the bodywork on the side of the car covering the oil cooler (6), engine control unit (21) and water radiator (22). The side pod and its components aid in engine cooling, car aerodynamics and driver protection in case of a side impact.

FUEL CELL: The fuel cell is made of rubber and is covered with a Kevlar-fitted blanket for extra protection in side impacts. It holds 22 gallons of 100 percent fuel grade ethanol.

GEARBOX/BELLHOUSING: An IZOD IndyCar Series car features an assisted gear shift system utilizing paddle shifting. Paddles are located on the back of the steering wheel, with the right paddle moving up gears and the left paddle moving down gears. The bellhousing connects the gearbox to the engine. Key components of the gear box/bellhousing include the oil scavenger tower (11), rear anti-roll bar assembly (12), rear damper/spring assembly (13), transmission (14) and rear attenuator (28).

ENGINE: The IZOD IndyCar Series utilizes the normally-aspirated, 3.5-liter Honda Indy V-8 engine has 650 horsepower. It has four valves per cylinder. The 3.5 liter provides longer engine life between rebuilds and additional mid-range torque for the varied IZOD IndyCar Series schedule – from street/road courses to short ovals to superspeedways. The engine houses the exhaust system (25) and the air box (26).

TIRES: Firestone Firehawk racing radials are mounted on 15-inch rims with front tires (1) approximately 11 inches wide and rear tires (29) approximately15 inches wide. The weight of an IZOD IndyCar Series car at is speed is approximately four times the static weight, so the tire sidewalls have to strong enough to handle the stress, yet thin enough to dissipate heat.

FRONT/REAR SUSPENSION: The front and rear suspension attach the wheels to the chassis. It is designed to withstand all the braking and acceleration loads in addition to vertical loads. The suspension includes the front brake disc (17) and rear brake disc (27).

1. OUTER SHELL: Designed to dispense energy in an

impact and protect from penetration from debris. The shell is made of an ultra-light, three-part weave of carbon fiber, Kevlar and fiberglass. It’s hand formed in a two-piece mold, then trimmed by a computer-controlled machine.

2. NOMEX LINING: Designed to transfer heat away from a driver’s head, while absorbing sweat. The thin fireproof layer is made of Nomex and Rayon and covers the inside of the entire helmet.

3. HATS-OFF BLADDER: A small air bag that can be inflated through a valve by safety crews allows the helmet to be lifted from the driver without neck strain. It was mandated by the IZOD IndyCar Series in 2003.

4. AERODYNAMIC PLATE: A small piece of outer shell which is attached to divert air into a gap beneath it to create downforce to stabilize the helmet. Air flow across the top of the helmet is directed into the engine air intake, located behind the driver’s head.

5. AERO WICKERS: Thin strips of rubber attached to each side and at the back of the helmet to prevent the driver’s head from being “buffeted” by 200 mph air resistance. It also prevents air back draft from trying to lift the helmet off. The shape is adjusted for each track.

6. INNER LINER: Made of a single molded piece of high-tech, lightweight bead foam, this is the helmet’s skeleton and the primary protective layer in an impact. It spreads both interior and exterior impact forces across a large area to protect the driver.

7. FIT PAD: Foam that surrounds the sides and back of the head glued to the inner liner. Thickness adapted to head size.

8. EAR PIECE: Allows the driver to hear in-car radio communication from the spotter and pits and protects the driver’s ears from engine noise. Also included is the Delphi Earpiece Sensor System, which measures the forces a driver’s head experiences in an impact.

9. NECK PAD: A strip of plush, open-cell foam attached to the inner liner at the base of the helmet. Like the fit pad, it is custom-made to ensure a tight fit around the neck. It also helps repel flames from the head and face.

10. CHIN STRAP: Kevlar strap secures the helmet to the driver’s head. It is replaced after minor accidents.

11. LID BALANCE: A part of the outer shell, it is a crucial aerodynamic aid to stop the driver’s head from being blown back at speed.

12. FRONTAL LINER: Extension of the main foam bead lining to protect the face in impacts. A microphone is imbedded into the foam in front of the driver’s mouth for in-car radio communication. Also houses the tube connected to the drink bottle installed in the front of the car.

13. VISOR: Able to repel fire for at least 45 seconds, the Lexan face shield is specially coated on the inside to prevent fogging. On the outside, three to five transparent, thin plastic “tear offs” allow the driver to.

2. NOMEX LINING: Designed to transfer heat away from a driver’s head, while absorbing sweat. The thin fireproof layer is made of Nomex and Rayon and covers the inside of the entire helmet.

3. HATS-OFF BLADDER: A small air bag that can be inflated through a valve by safety crews allows the helmet to be lifted from the driver without neck strain. It was mandated by the IZOD IndyCar Series in 2003.

4. AERODYNAMIC PLATE: A small piece of outer shell which is attached to divert air into a gap beneath it to create downforce to stabilize the helmet. Air flow across the top of the helmet is directed into the engine air intake, located behind the driver’s head.

5. AERO WICKERS: Thin strips of rubber attached to each side and at the back of the helmet to prevent the driver’s head from being “buffeted” by 200 mph air resistance. It also prevents air back draft from trying to lift the helmet off. The shape is adjusted for each track.

6. INNER LINER: Made of a single molded piece of high-tech, lightweight bead foam, this is the helmet’s skeleton and the primary protective layer in an impact. It spreads both interior and exterior impact forces across a large area to protect the driver.

7. FIT PAD: Foam that surrounds the sides and back of the head glued to the inner liner. Thickness adapted to head size.

8. EAR PIECE: Allows the driver to hear in-car radio communication from the spotter and pits and protects the driver’s ears from engine noise. Also included is the Delphi Earpiece Sensor System, which measures the forces a driver’s head experiences in an impact.

9. NECK PAD: A strip of plush, open-cell foam attached to the inner liner at the base of the helmet. Like the fit pad, it is custom-made to ensure a tight fit around the neck. It also helps repel flames from the head and face.

10. CHIN STRAP: Kevlar strap secures the helmet to the driver’s head. It is replaced after minor accidents.

11. LID BALANCE: A part of the outer shell, it is a crucial aerodynamic aid to stop the driver’s head from being blown back at speed.

12. FRONTAL LINER: Extension of the main foam bead lining to protect the face in impacts. A microphone is imbedded into the foam in front of the driver’s mouth for in-car radio communication. Also houses the tube connected to the drink bottle installed in the front of the car.

13. VISOR: Able to repel fire for at least 45 seconds, the Lexan face shield is specially coated on the inside to prevent fogging. On the outside, three to five transparent, thin plastic “tear offs” allow the driver to.